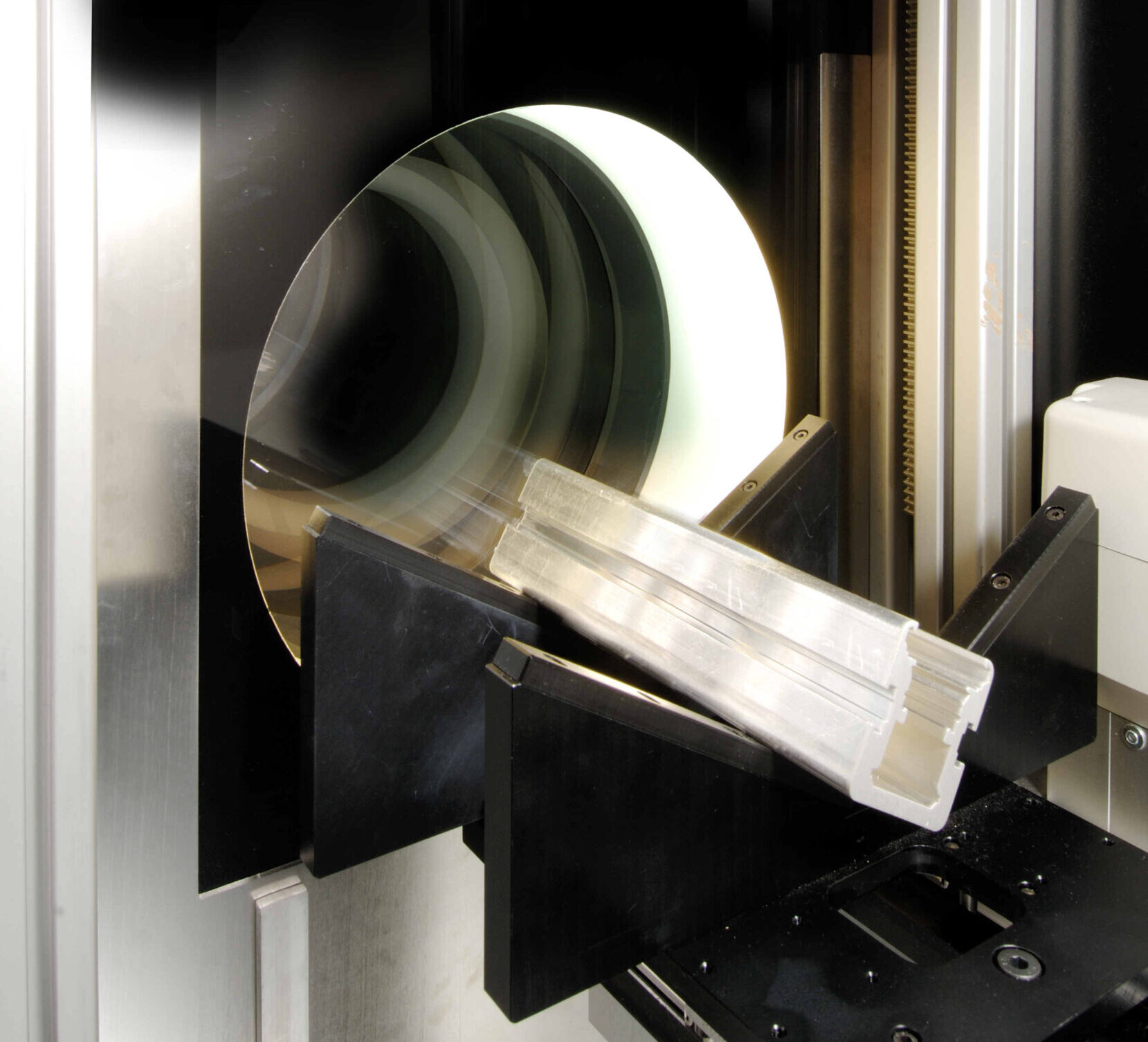

promex EXPERT 260

- Measuring Field Size: 260 x 170 mm, 260 x 300 mm, 260 x 500 mm, 260 x 700 mm

- Accuracy: ± 10 μm, ± 20 μm

- Measuring time: 2 - 5 sec.

- Material: Aluminum

- Location: Production, Laboratory

Precision and efficiency in optical profile measurement technology

Engineered with uncompromising accuracy and premium craftsmanship to deliver trusted performance.

Precise measuring results within seconds, optimizing efficiency and minimizing scrap in profile extrusion.

We stand behind our quality - if you're not satisfied, we offer a full refund, no questions asked.

Our systems and software are designed for intuitive use, ensuring seamless operation without the need for extensive training.

Our commitment to quality and innovation has earned the trust and satisfaction of customers worldwide.

Quality assurance plays an essential role in the production processes of manufacturing companies all over the world. Precise measurement technology combined with efficient and sustainable production processes are the key to top quality. Discover ASCONA solutions tailored to your industry.